Due to common carriers' increased dimensional weight charges, extra fees for large and lightweight packages, this fabric is very expensive to ship. Bolts or orders of 10 yards or more incur a higher shipping charge due to dimensional weight issues. BUT our wonderful shipping staff have figured out how to lower the costs by splitting the bolts into two 20 yard pieces and using special boxes. No cuts available larger than 20 yards.

The Nylon F3 Fleece has a bit of shimmer, just enough stretch and beautiful dye capabilities along with, of course, seam hiding. When this fabric was created, great care was taken to design a fabric with enough pile to easily hide seams but not too much to get in the way and look messy. The back is smooth and strong to help ensure solid stitching throughout the life of a puppet. With a tight knit and a smooth back, the fabric allows the builder to get the details you need but also get tight stitches and clean lines. With just a pull and rub, the pile helps cover the seams easily and effortlessly. Unlike some of the other puppet fabrics, this mix of nylon fibers creates a bit of a rougher surface allowing for easier cleaning and more durability plus that extra shine for the camera!

Fabric Details

- 100% Nylon (Nylon is NON-Flammable)

- 11 oz per square yard, 58" wide

- You can dye this with our Acid Dyes

- Suggested usage; Costumes, puppet and stuffed animal construction, fun fuzzy projects with kids, lap or personal blankets, therapeutic snuggling, robes, light jackets, hoodies, and other warm things.

- We found that this shrinks 2% in Length and 4% in Width disclaimer

- Available in cut yardage (bulk discounts levels at 10+ yds.) and in 40 yard boxes (No cuts available larger than 20 yards)

- Dyeing by hand is recommended (use more water then you would with normal fleece), and stir a LOT - these suck up the dye so fast, the fleece can dye unevenly unless constantly moving.

- Rinse under the tap with warm to hot water and lay out flat to dry

Remember, bolts vary! They can be over or under - we charge you for the actual yardage. If you need very specific yardage, order cut yardage.

There are a few things you should know about our fabrics...

Please note: Stripes can appear from improper control of dyeing temperature and the length of time. The Nylon has to take enough time in the bath, meanwhile it must maintain a constant temperature control (nylon is about 90~100 degrees Celsius ). Then it must be kept warm for 20~30 minutes after dyeing.

Made in: TAIWAN (TW)

Due to the volume of this product, shipments may incur dimensional weight charges. We've done our best to figure out how to package it in order to lower costs. Bolts now come boxed in two 20 yard pieces. No cuts available larger than 20 yards.

Dyeing F3F Puppet Fleece with Acid Dyes

Newest batch of F3 Fleece testing with Acid Dye 3/1/23

Method: Solid color acid dye procedure. Being careful to heat dyebath to between 194.0 °F- 212.0 °F (90~100 degrees Celsius), this heat is maintained for 30 minutes, during the dye process and then kept warm for 20~30 minutes after dyeing.

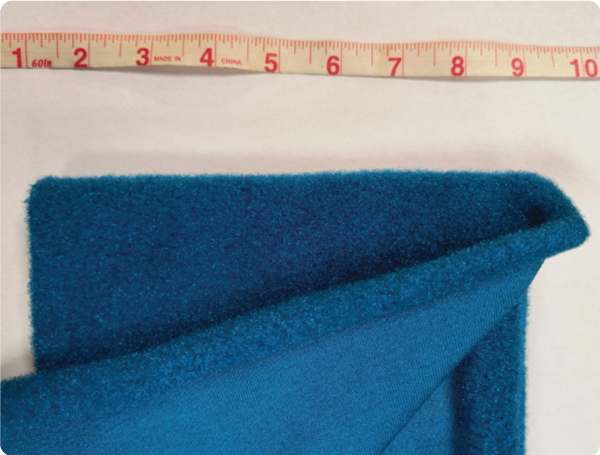

Tools: Test #1 with a Leveling Acid dye color: F3 Fleece 4 ounce sample (¼ yard), Dharma Acid Dye color #416 Peacock Blue dyed at 1.5% OWG = 0.06 oz., Citric Acid: 1/2 Tbsp.

Notes: Added water, dye and pre-dampened fabric to pot of water and placed on stove. Brought heat up to 190.4 degrees, after approximately 15 minutes of stirring to integrate the dye and fiber, added the Citric Acid to the pot (scrunched fabric aside and poured into dye solution slowly over a few minutes, stirring as I went). Maintained heat around 195 degrees for 30 minutes. Then turned down the heat and kept pot at warm for 25 minutes. Let pot then reduce to room temperature, removed item, rinsed in cold water and then washed with textile detergent.

*Result: Fleece dyed with Dharma Acid Dye color #416 Peacock Blue

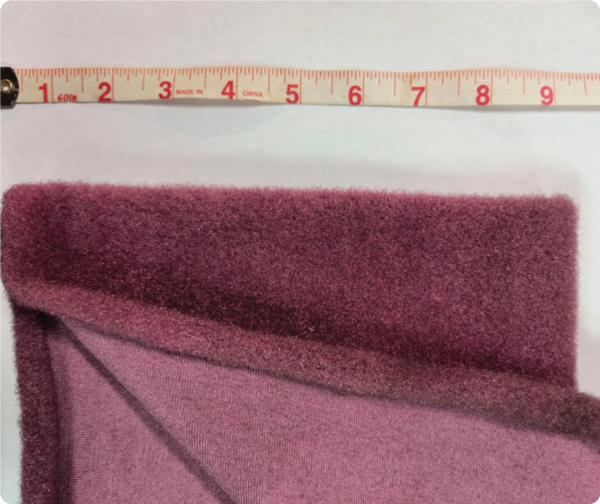

Test #2 with Pre-metallized/ advanced Acid dye color: F3 Fleece 4 ounce sample (¼ yard) Dharma Acid Dye color #432 Antique Mauve dyed at 1.5% OWG = 0.06 oz. Ammonium Sulfate: ½ Tbsp.

Notes: Added water, dye, Ammonium Sulfate and pre-dampened fabric to pot of water and placed on stove. Brought heat up to 190.4 degrees. Maintained heat around 195 degrees for 30 minutes. Then turned down the heat and kept pot at warm for 25 minutes. Let pot then reduce to room temperature, removed item, rinsed in cold water and rinsed again with textile detergent.

*Result: Some edges ended up a tiny bit splotchy - but overall very good result. Suspect that the advanced dyes are more picky with how they strike on nylon as the nylon needs to hit that high temperature for best results.